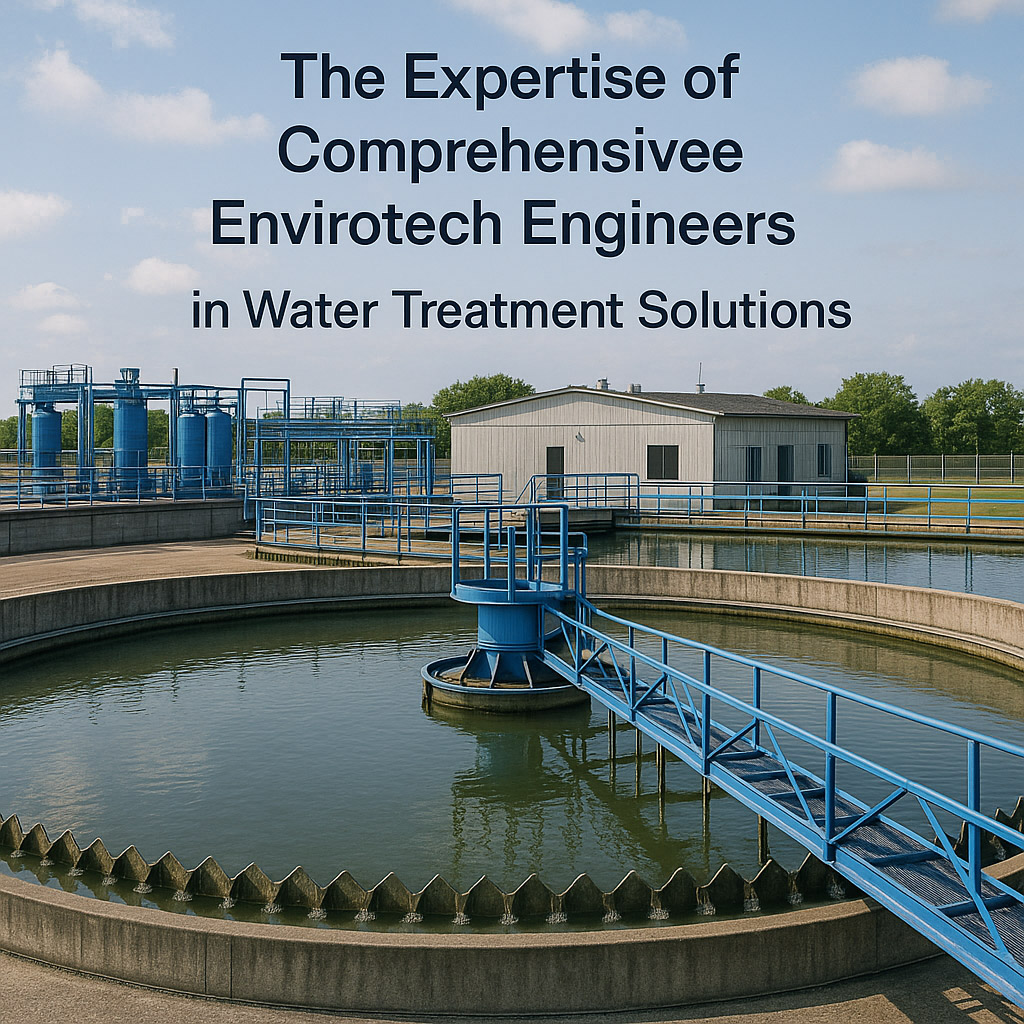

Industrial and infrastructure sectors in India today operate under a labyrinth of environmental laws, evolving standards, and public expectations. Comprehensive Envirotech Engineers Pvt Ltd has navigated this terrain for over two decades, and its experience offers valuable lessons on how engineering firms and clients can jointly overcome compliance challenges.

First, regulatory fluidity is a major hurdle. Rules related to air emissions, effluent discharge, hazardous waste, and solid waste are frequently updated by central and state pollution control boards. A project designed to one standard may quickly become non-compliant if norms tighten. To preempt this, Comprehensive Envirotech emphasizes designing systems with future headroom i.e., modularity and flexibility to scale or upgrade.

Second, site variability and incoming pollutant load fluctuations pose design risks. Many compliance failures occur because the treatment plant was over- or under-designed for real-world variations. The company combats this with extensive site sampling, pilot tests, and dynamic modeling before final engineering.

Third, stakeholder coordination is essential. A plant may require clearances from multiple agencies local municipal, pollution boards, forest departments, water boards. Comprehensive Envirotech often collaborates with legal specialists and regulatory consultants early in project planning to align engineering design with permit constraints.

Fourth, budget constraints vs quality tradeoffs is a recurring tension. Some clients may be tempted to cut costs by undersizing equipment or using lower-grade materials. The firm’s philosophy is that under-engineering often leads to long-term failures, frequent breakdowns, non-compliance penalties, and reputational damage. Instead, they advocate value engineering optimizing design without compromising core performance.

Fifth, operation & maintenance (O&M) gaps are one of the weakest links in compliance. Even a perfectly designed plant will fail if operators are untrained, spare parts are delayed, or monitoring is sporadic. Comprehensive Envirotech assists clients with training modules, O&M service contracts, remote monitoring, and performance audits, bridging the technical and operational divide.

Sixth, public perception and transparency are increasingly non-negotiable. Communities and NGOs monitor industrial impacts, and any violation becomes a public issue. Having real-time dashboards, public-facing metrics, compliance reports, and citizen engagement helps mitigate backlash. The firm encourages clients to adopt open reporting where feasible.

Finally, risk mitigation & contingency planning is vital. Treatment plants may experience blowdowns, power outages, upsets due to load surges, etc. Comprehensive Envirotech’s designs incorporate buffer tanks, redundancy, alarm systems, bypass protocols, and emergency response plans to ensure compliance continuity.

By internalizing these lessons and collaborating closely with clients, Comprehensive Envirotech Engineers helps transform compliance from a reactive burden into a proactive, managed process. Their experience, grounded in decades of regulatory cycles and project learnings, positions them as advisers who not only engineer solutions but foresee challenges and build resilience.